ESPE Measurement

ESPE MEASUREMENT / MACHINE DOWNTIME MEASUREMENT ESPE Measurement (Measurement of downtime of machines) is one of the important measurements made to determine whether the guards in the machines are positioned appropriately according to the approach speeds of various parts of the human body.

ESPE measurements made with reference to EN ISO 13855 standard are applied for the following protective equipment;

a) electro-sensitive protective equipment, including:

⎯ light curtains and light grids (AOPDs);

⎯ laser scanners (AOPDDRs) and two-dimensional vision systems;

b) pressure-sensitive protective equipment, especially pressure-sensitive mats;

c) two-hand control devices;

d) interlocking guards without guard locking.

As EUTEST, we make position verifications by measuring the downtime of the protective equipment you use in your machines, and we determine the minimum safety distances that must be provided and report them to you.

Contact us for machine downtime measurements that should be applied within the scope of the safety of machines.

As stated in the "HEALTH AND SAFETY REGULATIONS FOR THE USE OF WORK EQUIPMENT" published in the Official Journal dated 25.04.2013 and numbered 28628, there is no accreditation obligation for the periodic inspection of work equipment, however according to the aforementioned regulation, the accreditation obligation will begin for the following equipment after 31.12.2023:

1. Tower cranes

2. LPG tanks and their means (underground and above ground)

3. Escalators

4. Suspended access equipment.

CE Mark is a conformity and safety mark created in 1985 in order to ensure the free movement of goods between countries within the framework of the Customs Agreement of the European Union.

The CE mark is a mark that indicates that the products sold in Turkey and the European Economic Area (EEA) are evaluated to meet the high safety, health and environmental protection requirements and their conformity. For this reason, "CE" marking is a mandatory requirement for a product to be sold and used in Turkey and the EEA.

By affixing or ensuring that the "CE" mark is affixed to its product or to the information plate on the product, the manufacturer is deemed to have declared such it is under his own responsibility a certain the product complies with the relevant technical regulation or regulations that require this marking and a particular the product has been subjected to all necessary conformity assessment procedures.

CE” mark;

It consists of the letters "CE" and has a minimum size of 5 mm, unless otherwise stated in the relevant technical regulation.

In cases where it is not possible to affix the CE mark on the product or its permanence cannot be guaranteed due to the nature of the product, it is placed on the product's packaging and the documents accompanying the product in a visible, legible and indelible manner.

CE marking is mandatory in all countries that are members of the European Union.

Turkey and Switzerland are not members of the European Union, however the CE mark is obligatory in these countries just like the European Union.

It is the proving/certification that a manufactured product complies with previously accepted technical regulations or harmonized standards and meets minimum health and safety requirements for humans (and as appropriate, animals) and the environment.

If a product is placed on the market or put into service, it must have the CE mark.

For example, in the scope of the 2006/42/EC Machinery Directive, “Put Into Service” refers to the first use of the machine for its purposes.

In addition to the tests, before the machine is put on the market;

Documentation (technical file),

Labeling,

Drawing up the EC/EU Declaration of Conformity and

If necessary, evaluations by third-party certification bodies

are also required.

If the components of the final machine are in scope of CE regulation, they must be chosen from CE marked components. However, it is not sufficient by itself to select all components as CE marked, to confirm CE requirements for final products. The final product should be evaluated acc. to Machinery Directive and its nonconformities should be determined.

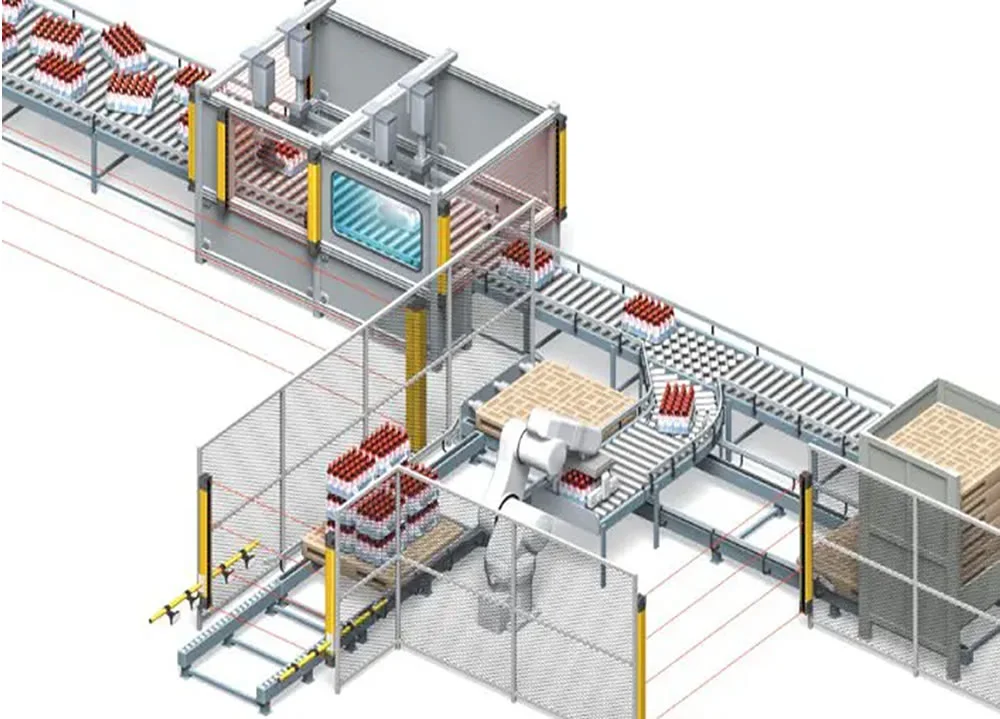

For example, a CE marked light curtain is used, but it may not be positioned at a sufficient distance, not selected with appropriate resolution, and its connections may not meet the requirements.

The machine was established to improve the design and make revisions in line with customer demands. In any case, changes will be made on the machine.

This, does not constitute an excuse for delaying CE marking and taking safety measures. All responsibilities regarding CE marking must be fulfilled before the machines are placed on the market or put into service for the first time to use in its intended purposes.

Adding or replacing a machine on a CE marked production line may require reassessment. The interaction of the added or modified machine with other machines is taken into account. If additional risks arise, these additional risks affect other machines and if the existing measures are not sufficient for these new risks, the production line must be re-evaluated according to the Machinery Directive.

It is possible if the regulation to which the product is subject allow it. However, CE marking should not be underestimated and should not be taken as just a marking or a declaration.

In order to affix the CE mark to the product, all technical safety requirements of the product must be fulfilled, all documents that make up the technical file must be prepared and, if necessary, safety tests must be carried out.

In addition to the above, when deemed mandatory in the regulations, the product must also be assessed and certified by third-party organizations (NOBO).

FOR MORE INFORMATION

Contact us

EUTEST

Altınşehir Mh. Kelebek Sk. No:4 D:4

Ümraniye/İstanbul

Phone: +90 216 540 49 59

E-Mail: [email protected]